PROJECT IN BRIEF

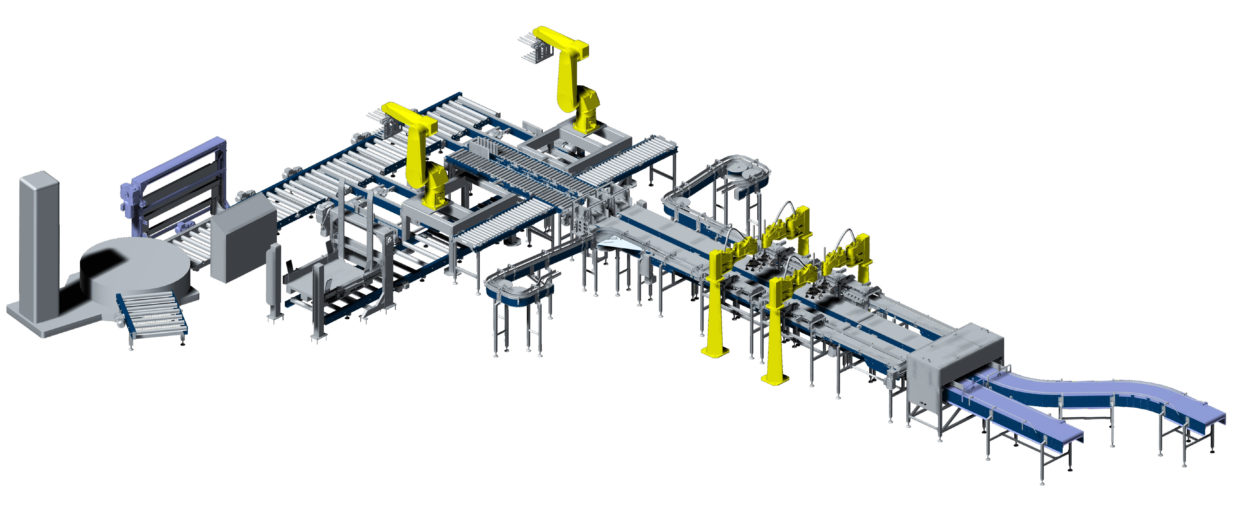

- Complex service We prepared a solution proposal, took care of the trial operation in TMT and on-site implementation.

-

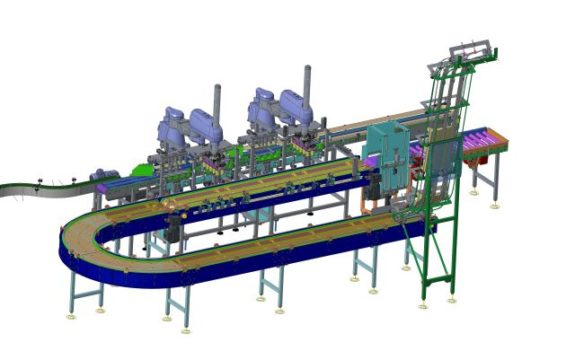

Transported Loads

Paper trays

Wooden pallets

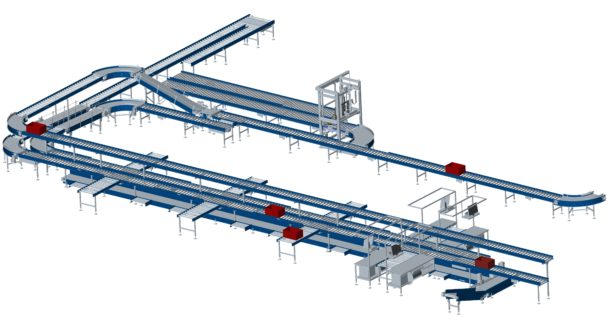

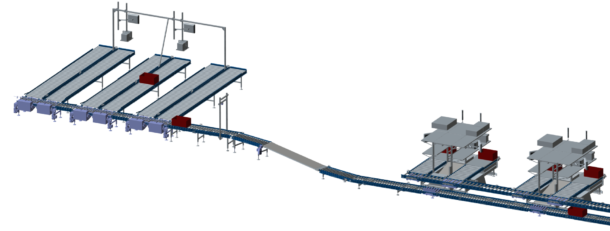

Plastic cups - EFFICIENT USE OF SMALL SPACE The dimensions of the new line are 22 x 12 m. The total length of the conveyors is around 77 m.

-

REDUCTION OF THE NUMBER OF OPERATORS

Twelve manual operators were replaced

by 6 robots and 2 operators.