PROJECT IN BRIEF

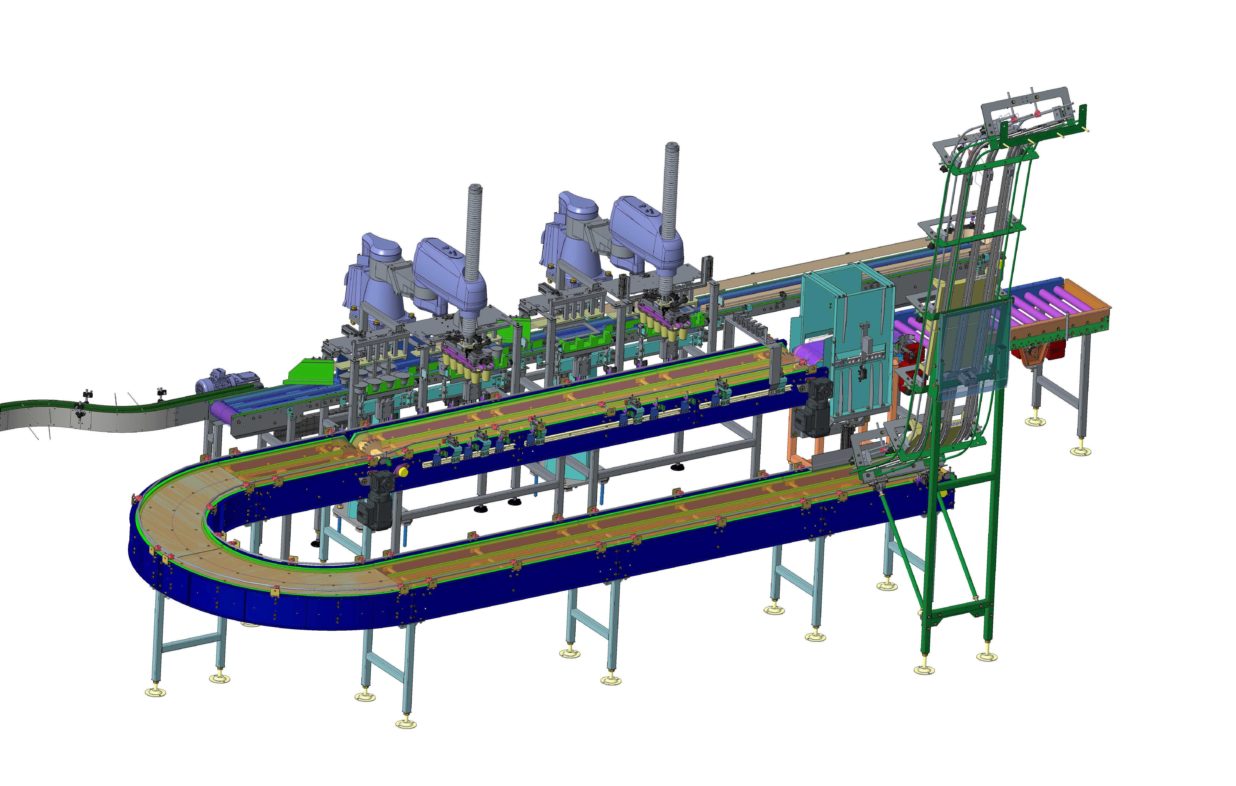

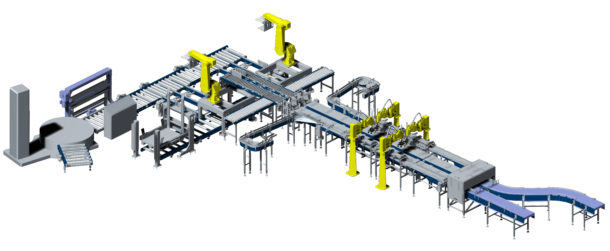

- COMPLETE SERVICE We developed the design of the solution, took care of the test run in TMT and the final implementation.

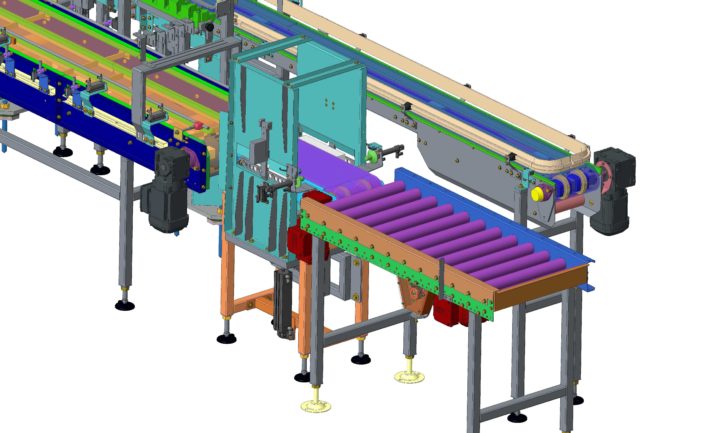

- VARIABILITY - DIFFERENT RANGE OF CUPS The line is designed for plastic cups with 2 different lid diameters (75 mm and 95 mm) and different heights. The capacity of the line is 7 000 pcs/hr.

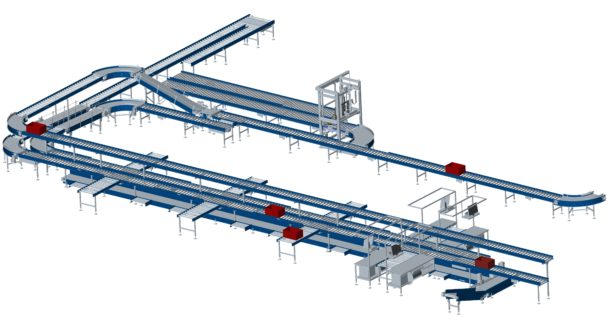

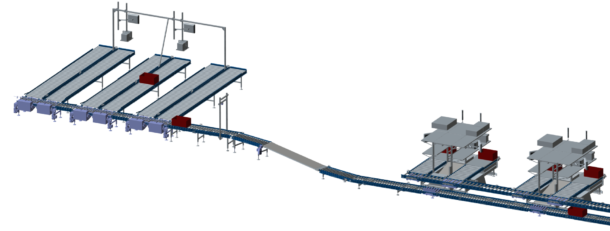

- PRODUCTION CONSOLIDATION Replacement of many older machines with one modern robotic line.

- EFFICIENT USE OF SMALL SPACE The dimensions of the new line are 3 m x 7 m.