Warehouse technology

palletizing

packaging lines

Why automation

Distribution centres

We always take into account the all aspects of the operation, the range and the required performance, focused primarily on productivity and reducing errors. We will prepare a tailor-made project for the automation of storage, picking and packaging.

Warehouses

With TMT you will optimally serve your warehouses in automatic mode. We solve unattended handling, storage of crates, cartons and other transport units.

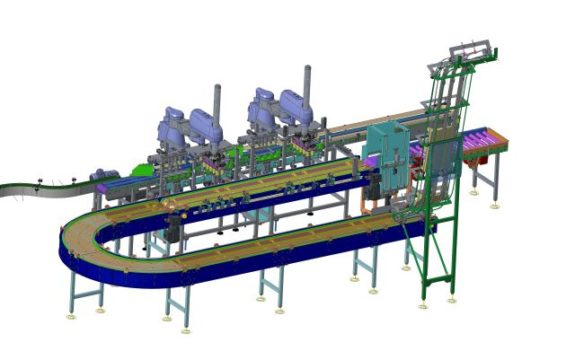

Palletizing - packaging lines

Storage and packaging of products also play an important role. We enable you to store and pack reliably and with smart pallet logistics. Our pallet conveyors are used to transport goods on pallets and trolleys of various sizes.

Warehouse technology

Fully Automated Warehouse

Unattended handling and storage of crates, cartons or other transport pads takes place here. There is an automatic warehousing and removal of goods from storage positions. Identification and dimensional control takes place before entering the system.

Automated Stackers

The automatic system is used for loading and unloading goods from the rack to the shipping line. The exact position of the stacker is sensed by an integrated actuator with zero point control in both extreme travel limits. The track scanner checks the throughput of the path.

Distribution Line

The use of stackers and destackers to store empty packaging (cases, pallets) facilitates handling and streamlines processes.

For one of the largest sellers of sanitary equipment – SANITINO, we made a conveyor line for transporting KLT boxes with goods. Read how everything works in practice.

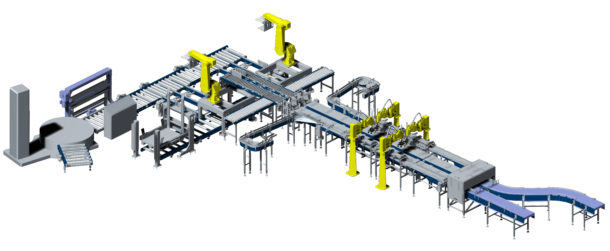

Sample - Distribution Warehouse

The conveyor system in the distribution warehouse is designed for the transport of plastic crates or cardboard boxes between storage locations (picking, packaging) and packaged consignments for dispatch.

IDENTIFICATION AND SORTING OF SHIPMENTS

The basis of the process are roller conveyors, supplemented by sorting modules, translators, gravity spiral conveyors, gluing and strapping machines or checkweighers. They include shipment flow control systems with barcode reading identification.

PICKING AND PACKAGING

A comprehensive conveyor system is used for the preparation of goods, the completion of consignments from several picking boxes and the final packaging workplace. Egronomically designed packaging workplaces, in addition to packaging tables of various designs, contain other accessories – readers, label printers, sockets, LAN wiring, fans and more as needed.

Palletization - Packaging Lines

Automated and Robotic Palletization

Automated and robotic systems facilitate all product movement, packaging, palletizing, storage and distribution. They handle a wide range of packaging, such as boxes, cartons, trays or crates, and pallets. The palletizing line uses infeed conveyors of goods, pallets and packaging materials.

Transport Line of Heavy Pallet

The line allows transport, loading, turning or lifting of pallets. Labelers, wrappers, strapping machines or scales can be integrated into industrial lines.

Expedition Line

Loading and unloading point – adapted for the possibility of further handling of the pallet using a pallet truck or forklift.