Project in brief

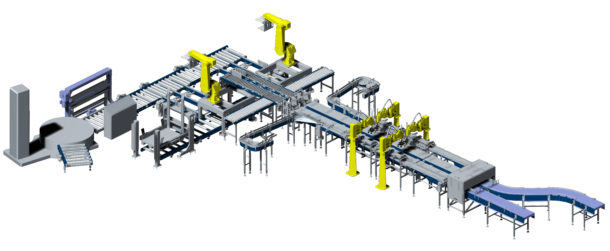

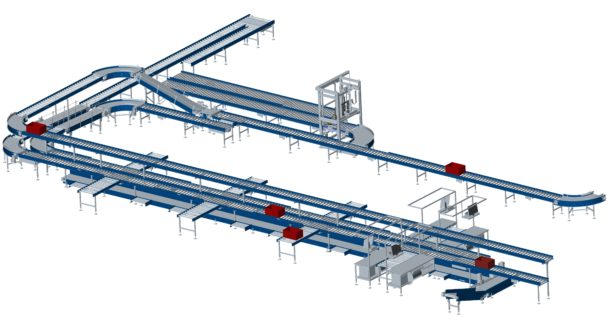

- Performance increase We have increased the line's performance from the previous 400 shipments per hour to the current 720.

- Complete realization We processed the entire project from the design of the solution to its successful completion.

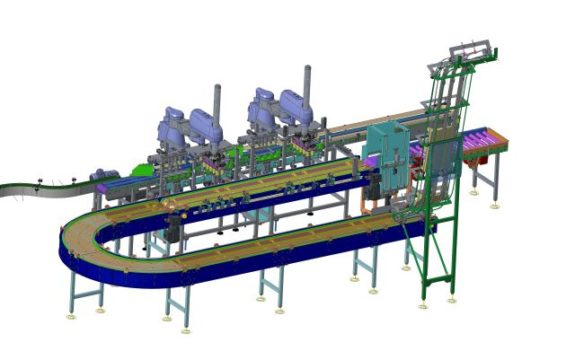

- Faultlessness We have implemented integrated shipment weighing control systems.

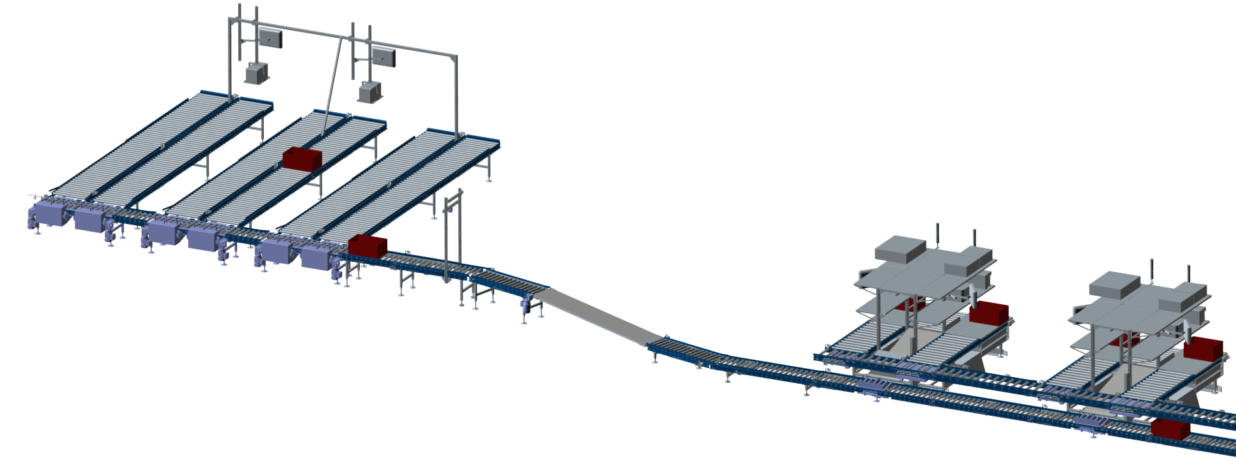

- Transported loads We made belt conveyors for KLT crates and cardboard boxes.

- Speed of delivery The entire implementation took 5 months from the signing of the contract to the handover of the contract.