Chemistry & Pharmacy

Why automation

Effective solution tailored to you

We always take into account the nature of the operation, the range and the required performance, focusing on productivity and reducing errors.

PERFORMANCE, SAFETY, ERGONOMICS & RELIABILITY

No more chaotic manipulation. Everything has its system and is centrally managed. In addition, you can increase the accuracy of the performance by connecting robotic elements.

PRODUCTIVITY INCREASING

Don't waste your time and money. The logistics of the supply of input material to the finished product can flow without unnecessary downtime.

ERROR-FREE ASSEMBLY

Our automated workplace efficiently solves the operation of assembly and control elements of production lines. We rely on accuracy, performance and safety.

Chemistry & Pharmacy

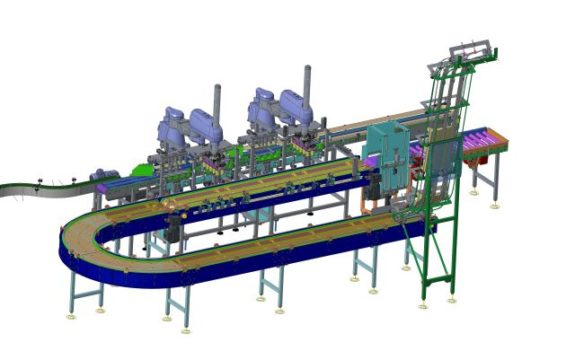

HEIGHT TRANSFER OF PALLETS

The continuity of the roller routes at different heights is ensured by the lifting section.

ROLLER CONVEYORS FOR PALLETS

BOXES PUSHER

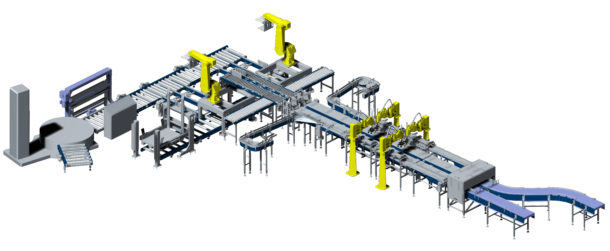

Box conveyor for bulk mixtures

The main conveyor belt is installed in the suction cabinet. The lower discharge conveyor continuously cleans the cabinet area.

PLATE CONVEYORS OF PACKAGED PRODUCTS

Sorting module