Production and Assembly Lines

Industrial Production

Robotization

Why automation

PRODUCTION & ASSEMBLY LINES

Do you want to increase performance or expand production? TMT's technical solutions will find application from the receipt of material to the expedition of finished products and in many other additional services.

INDUSTRIAL PRODUCTION

Do lack of staff or insufficient production equipment prevent you from generating higher profits? You can use TMT automated conveyor systems in many industries.

ROBOTIZATION

Do you need to speed up the packaging and handling of products? We supply everything you need at robotic workplaces, speed up and make product handling more accurate.

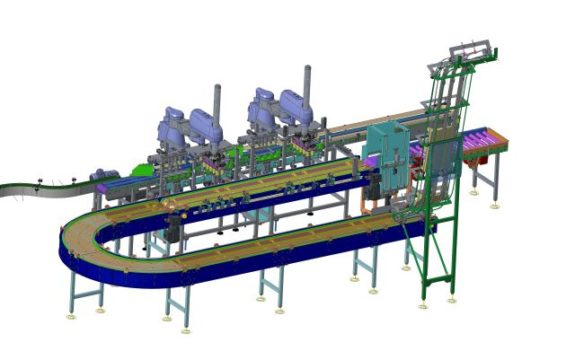

PRODUCTION & ASSEMBLY LINES

CONVEYORS BETWEEN WORKPLACES

Conveyors (roller, roller, chain-storage, etc.) ensure efficient transfer of work-in-progress products between workplaces. Stoppers and fixing positions are used for precise positioning for robots and other automatic operations. Other additional devices allow turning, lifting or overturning of products.

WORKPLACES ON ASSEMBLY LINES

Automatic or manual workplaces are designed with regard to technological requirements such as assembly, inspection and other. We integrate technologies for automatic screwdriving, lubrication, laser cutting and marking, labeling, camera inspections, material containers and many other accessories.

SPECIAL PALLETS AND PREPARATIONS

Single-purpose assembly pallets and jigs fundamentally define the purpose of the use of assembly lines. We design and supply special jigs, for example, for the assembly of car seats, air conditioning units, cockpits, etc. assembly kits.

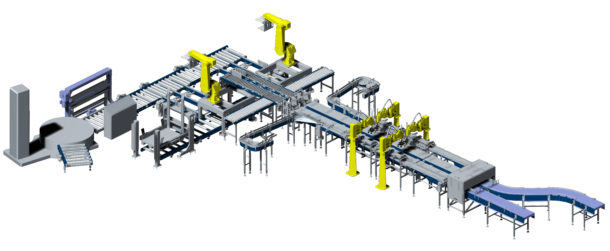

Robotization

PACKAGING & PALLETIZATION AUTOMATION

Robots are involved in the process of packaging and palletizing the final products. This significantly speeds up the shipment of products and reduces the requirement for “manpower”. Packaging and palletizing automation includes conveyors, handling and palletizing robots, and integrates machines for packaging, fixing, identification and marking of products. Production line control systems work closely with superior MES systems (SAP, WMS,…)

PRODUCT ROTATION IN ASSEMBLY LINE

LASER WORKPLACE

Using laser technology, we solve the processes of cutting, welding, degreasing, marking or surface treatment of various materials. Lasers excel in accuracy, speed and quality. The cost and environmental advantage is that they do not require additional consumables for most operations.

Industrial production

CONVEYOR SYSTEMS FOR INTRALOGISTICS

Intralogistic conveyor systems respect the power and spatial dispositions according to the specific assignment. They ensure the transport of work-in-progress products and packaging within operations. Walking steel platforms may be included for the installation of roller, belt or chain conveyors. To overcome vertical differences, sloping sections or lifts are included. Automated warehouses handle unattended warehousing processes.

INCOME AND EXPEDITION LINES

Receipt and dispatch lines represent the boundaries of the conveyor systems of production plants. These parts of the lines contain modifications and equipment for checking the number, weight, order, marking, etc. Receipt and dispatch lines can be connected to automated warehouses or AGV technologies.