Conveyor Line for the Mutěnice Greenhouse – Tomato Handling

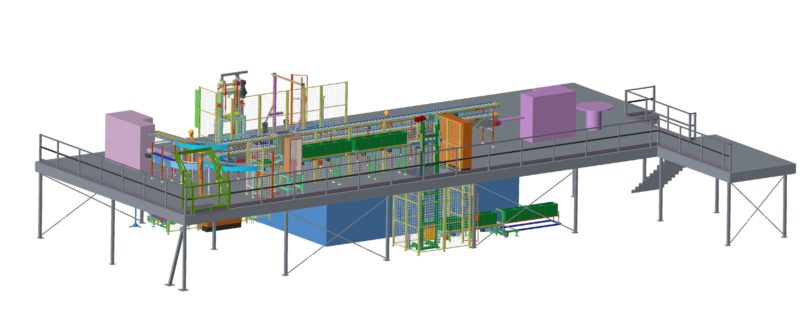

An interesting conveyor line designed for transporting tomatoes in plastic crates between floors, followed by packaging into paper trays and preparing for dispatch.

The customer’s request was to speed up the entire tomato handling and packaging process within a relatively limited space. For this reason, a new floor was built, allowing us to install our conveyor line.

Conveyor and packaging line for tomatoes

How does the line work?

Using an elevator, full crates of freshly picked tomatoes from the greenhouse are transported to the first floor, where up to eight stacks of crates can accumulate on the roller conveyor. At the end of the accumulation section, a destacker is installed. The destacker separates the stacks and releases individual crates onto the line.

These then travel through roller bends and accumulation roller conveyors to the workstation, where operators remove the crates from the line, weigh the tomatoes, and place them into paper trays.

The trays filled with tomatoes are then placed by the operator onto a belt conveyor, which transports them to the packaging machines. The packaging machine wraps the trays in transparent foil, after which the worker places the trays into crates and arranges them on a pallet.

The packed and palletized goods are then moved by a pallet truck to the elevator, which transports them down to the ground floor (0th level), ready for dispatch.

In case of a breakdown of one of the packaging machines, the belt conveyors can be reversed to direct the trays to another functional packer.

Empty crates are placed on the upper roller conveyor, which transports them to the point where operators restack them onto an EUR pallet. Using pallet conveyors and the elevator, the empty pallets are transported back down to the ground floor.

The pallet lift/elevator also ensures the transport of packaging materials from the ground floor to the first floor.

Handling Units

- Plastic crates: 400 × 600 × 100 mm – approx. 6 kg

- Stacks of crates: 400 × 600 × 460 mm – approx. 30 kg

- Paper trays: 120 × 250 × 30 mm – approx. 250–500 g

- EUR pallets: 800 × 1200 × 2000 mm – max. 800 kg

Conveying capacity: up to 300 crates/hour

Hall environment: +5 °C to +40 °C

This project demonstrates that a well-designed, custom-built conveyor line — tailored precisely to customer requirements — can significantly improve your productivity and efficiency.

And if you ever need advice or assistance, don’t hesitate to contact us.