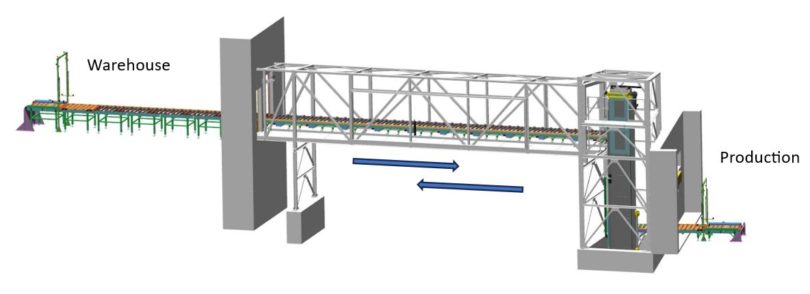

Pallet conveyor line between warehouse and production building

We recently completed the supply and installation of a conveyor line For Heinz-Glas Decor, a leading manufacturer of glass bottles and jars in the cosmetics and perfumery sector. This line provides a link between the new warehouse building and the existing production building.

We efficiently solved the customer’s problem of transporting material on pallets by using the conveyor line. The conveyor line overcomes the distance between the connected buildings and at the same time a considerable height difference.

The conveyor bridge is delivered with regard to the visual architectural design required by the customer.

Basic parts of the conveyor line

- Receiving section (warehouse building)

- Connecting route (bridging)

- Lifting section (production building)

- Receiving section (production building)

Line description

The conveyor line is designed for bidirectional transport of pallets with material between the warehouse building and the production building.

The line operator places the pallet on the loading conveyor in the warehouse (production) and leaves the loading area. The pallet is automatically transported by the line from the warehouse (production) building via a conveyor bridge to the production (warehouse) building. The line operator removes the transported pallet.

For handling, the operator uses a front-fork electric trolley and a manually guided electric trolley.

Pallets are accumulated within the length of the conveyor line.

Two-way transport of pallets between buildings - conveyor bridge

Transported load

Pallet type:

- EUR pallet

- Industry pallet

Dimensions:

- 800 × 1200 mm, height with material max 1150 mm

- 1000 × 1200 mm, height with material max 1600 mm

Weight of pallet with goods:

- max 850 kg

Transport capacity of the system, accumulation capacity

- Required transport capacity – pallets/hour in one-way operation

- Maximum transport capacity – 30 pallets/hour in one-way operation

- Total storage capacityt – 20 pallets

Transport and supplementary equipment

- roller conveyors – in lengths, number and design according to the project

- hoist with turntable and roller conveyor

- tandem high-speed service door and fire shutter (for both buildings concerned)

The conveyor line is supplied with associated electrical and control components.

Safety of the conveyor line

The conveyor line is designed for operator safety and fire safety in accordance with legislative requirements.

Is this an interesting realization for you? Do not hesitate to call us. We will be pleased to help you and prepare an offer.